Understanding Needle Guns

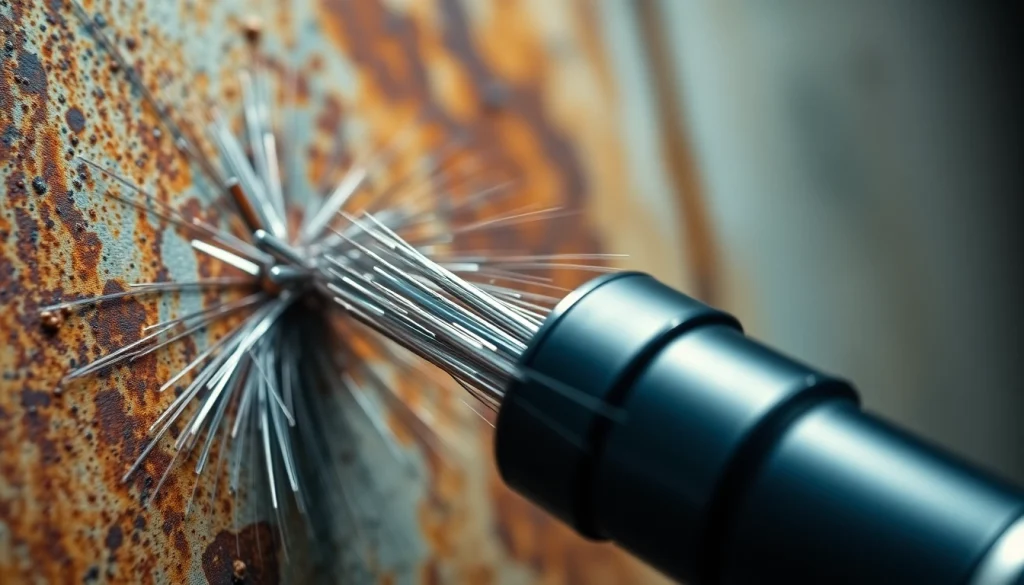

A needle gun, commonly known as a needle scaler, is a powerful tool designed for surface preparation. The mechanism behind a needle gun is relatively straightforward yet highly effective—a series of steel needles vibrate rapidly, which helps to remove rust, scale, paint, and other unwanted materials from various surfaces. This article will delve into everything you need to know about needle guns, from their types and features to safety practices and applications in various industries.

What is a Needle Gun?

A needle gun is a pneumatically powered tool that employs a set of small, high-speed needles to create a hammering effect, which efficiently strips surfaces of rust, paint, and grime. The design of the needle gun allows the operator to work not only on flat surfaces but also on irregular geometries, making it a versatile instrument in metalworking and repair. Manufactured primarily from durable materials to withstand heavy use, needle guns are invaluable in both industrial and DIY projects.

Types of Needle Guns

Needle guns come in two primary types: electric and pneumatic. Understanding the differences between these types helps in selecting the right tool for your needs.

- Pneumatic Needle Guns: These tools are powered by compressed air and are typically found in professional settings due to their higher power capacity. Pneumatic needle guns can produce higher beats per minute (BPM), making them extremely effective in heavy-duty scenarios. They require an air compressor, which significantly impacts their mobility and setup time.

- Electric Needle Guns: These models run on electricity, making them easier to use in a variety of settings, especially where air compressors are impractical. They tend to be quieter and lighter than their pneumatic counterparts, making them suitable for smaller jobs, home maintenance, and automotive repairs.

Key Features to Look For

When selecting a needle gun, certain features can enhance its performance and usability. Here are the key aspects to consider:

- Needle Quantity and Size: More needles can translate to faster and more efficient surface cleaning. Standard sizes often range from 12 to 18 needles, with configurations tailored to different tasks.

- Beats Per Minute (BPM): A higher BPM indicates a more vigorous cleaning tool, crucial for tackling tough rust and buildup. Typical BPM rates range from 4,000 to 6,000.

- Weight and Ergonomics: Lighter models ease fatigue during prolonged use. Ergonomically designed grips enhance comfort and control while operating.

- Adjustability: Some needle guns offer adjustable features to control the force of impact and speed, offering flexibility depending on the task.

Applications of Needle Guns

Needle guns are particularly useful in a wide range of industries. Understanding their applications can help users realize their potential in various projects.

Surface Preparation in Metalworking

In metalworking, needle guns are employed to prepare surfaces for painting, welding, and other treatments. The continuous hammer action produced by the needles effectively removes rust, old coatings, and other contaminants that would interfere with the adhesion and quality of subsequent treatments. This is crucial in industries where metal integrity is paramount, such as construction, manufacturing, and automotive sectors.

Automotive Repair Uses

In automotive repair, needle guns play a vital role in restoring vehicles. They can strip down surfaces to bare metal, allowing for the application of new coatings or repairs. This functionality is particularly sought after for tasks such as rust removal on car bodies, preparation of weld areas, and maintenance of exhaust systems. Their ability to reach tight spaces makes them an essential tool for automotive technicians.

Ship Maintenance Projects

Ship maintenance relies heavily on the use of needle guns due to the marine environment’s corrosive effects on metal. Regular upkeep of ships includes removing barnacles, paint, and rust from hulls to maintain performance and integrity. Needle guns can facilitate this process, ensuring that ships remain seaworthy and compliant with safety regulations.

Choosing the Right Needle Gun

When purchasing a needle gun, selection is key to ensuring suitable performance for specific tasks. Below are considerations that can guide your purchasing decision.

Electric vs Pneumatic Needle Guns

The choice between electric and pneumatic needle guns often hinges on the nature of the projects you anticipate undertaking. Electric models are ideal for home users and smaller tasks due to their ease of use and portability. In contrast, pneumatic models are better suited for heavy-duty work and industrial environments where an air compressor is available.

Selecting the Appropriate Needle Size

Needle size plays a crucial role in determining the effectiveness of the gun. Smaller needles provide better access to tight areas and detail work but may take longer to remove thick layers. Conversely, larger needles are suitable for broader surfaces but may not reach intricate designs effectively. Consider the scope of your work to select an appropriate needle size.

Considerations for Power and Air Requirements

For pneumatic needle guns, understanding the air requirements becomes critical. Most models require between 8 to 16 CFM at 90 PSI for optimal operation. Ensure that your air compressor meets these specifications to avoid underperformance.

Best Practices for Using a Needle Gun

Optimal performance from a needle gun requires an understanding of best practices regarding usage, safety, and maintenance.

Safety Measures and Guidelines

Using needle guns comes with inherent risks, primarily due to flying debris and high-speed operation. It is crucial to implement safety measures:

- Wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and ear protection.

- Ensure the workspace is free of flammable materials, as sparks may occur during use.

- Maintain a firm grip on the gun and understand how the tool operates before starting.

Efficient Techniques for Maximum Impact

Efficiency in using a needle gun revolves around technique. Here are effective methods to maximize results:

- Maintain Consistent Pressure: Apply steady pressure while moving the needle gun across the surface to ensure even removal.

- Work in Sections: Breaking up your work into manageable sections can provide better control and ensure thorough cleaning.

- Adjust Speed Settings: If available, adjust speed settings to match the surface type and condition for optimal outcomes.

Maintenance Tips for Longevity

Proper maintenance extends the lifespan of your needle gun and ensures it operates efficiently:

- Regularly clean the needles from debris and buildup after each use.

- Inspect the overall tool for any signs of wear and tear; replace any worn parts promptly.

- Store the tool in a clean, dry environment to prevent environmental damage.

Comparative Analysis of Popular Needle Guns

As the market is saturated with various needle guns, here’s a look at some popular models along with their features and user feedback.

Top Electric Needle Guns Reviewed

Electric needle guns have received accolades for their user-friendliness and portability. Key models often cited include:

- Powermate Pistol Type Air Needle Scaler: Known for its compact design and versatility, this model is perfect for rust and paint removal with an ergonomic grip for prolonged use.

- MCGRAW Compact Air Needle Scaler: Offers 4400 BPM and 12 hardened steel needles for efficient surface preparation, particularly rated well for automotive applications.

Comparing Pneumatic Models

Pneumatic needle guns are favored in professional settings. Top models include:

- LE LEMATEC Air Needle Scaler: This model stands out with its powerful hammering action, making it ideal for metalworks and rust removal.

- Trelawny Heavy Duty Needle Scaler: Known for excellent performance on steel and fiber surfaces, this heavy-duty model garners praise for its multiple needle design for contour following.

Customer Feedback and Product Ratings

Analyzing customer reviews offers insight into user experiences across different models. Generally, users appreciate tools that provide a balance of power and control. High bpm ratings and ergonomic designs are frequently highlighted as vital to effectiveness and user comfort.