Introduction to SMT Assembly

In the ever-evolving landscape of electronics manufacturing, smt assembly stands out as a pivotal innovation. This advanced technique allows for the efficient production of compact and reliable electronic circuits by mounting components directly onto the surface of printed circuit boards (PCBs). The methodology not only enhances production speed but also boosts the performance and reliability of the assembled products, making it an essential process in the electronics industry.

What is SMT Assembly?

Surface Mount Technology (SMT) assembly involves a method where electronic components are mounted directly onto the surface of a PCB, contrasting traditional through-hole technology, which requires components to be inserted into pre-drilled holes. This innovative approach simplifies the assembly process, allowing for improved placement accuracy and greater circuit density. SMT has become the preferred assembly method in many applications due to its ability to produce smaller, more streamlined electronic devices.

Benefits of SMT Assembly

The advantages of adopting SMT assembly are numerous:

- Space Efficiency: SMT reduces the footprint of circuit boards, enabling manufacturers to design compact devices without compromising performance.

- Higher Production Speed: The automated placement and soldering processes associated with SMT enhance production rates significantly.

- Enhanced Performance: Surface-mounted components create shorter paths for electrical signals, reducing signal loss and improving device performance.

- Cost Effectiveness: With less material usage and reduced assembly time, manufacturers can achieve lower production costs in high-volume operations.

Common Applications of SMT Assembly

SMT assembly is widely utilized across various sectors, including:

- Consumer Electronics: Devices like smartphones, tablets, and wearables heavily rely on SMT for their intricate circuitry.

- Automotive Industry: From engine controls to infotainment systems, SMT is critical for reliability and efficiency.

- Medical Devices: SMT facilitates the miniaturization necessary for compact medical devices that deliver critical functions.

- Industrial Equipment: Many manufacturing machines incorporate SMT parts for better reliability and performance.

Key Components of SMT Assembly

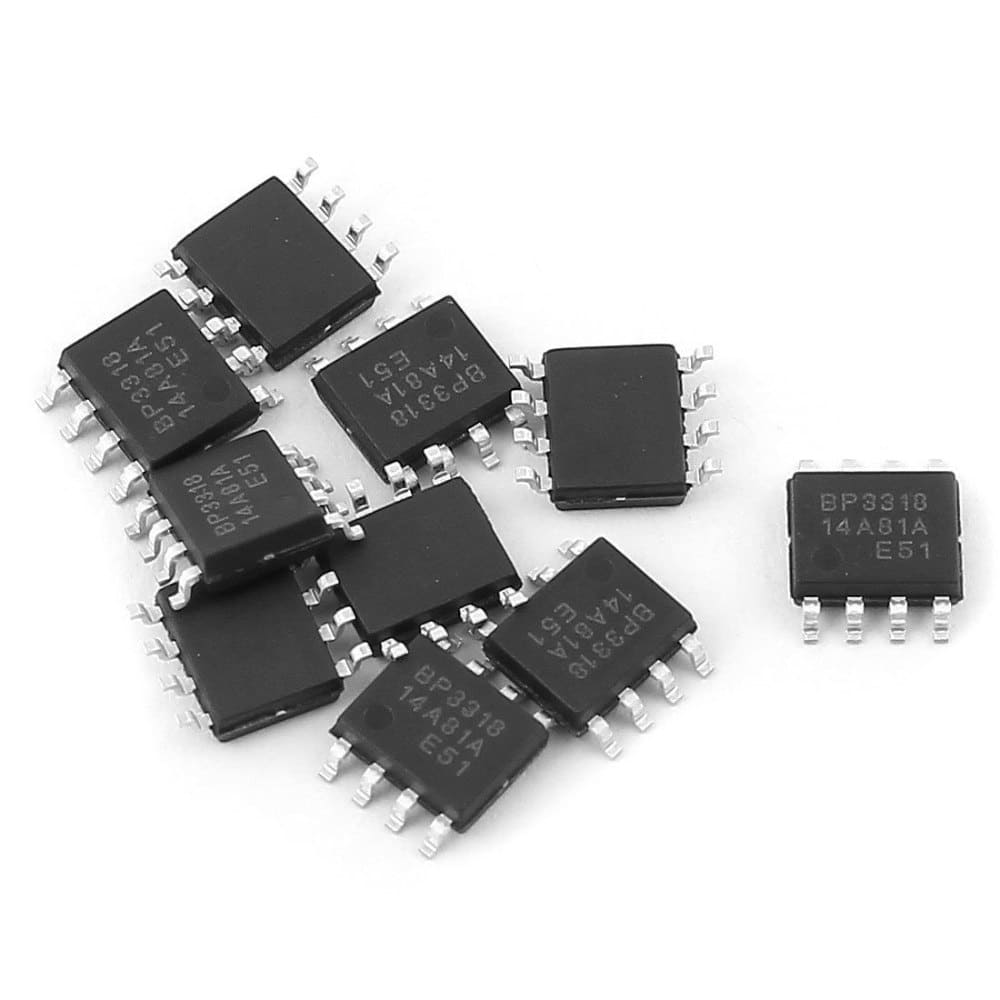

Surface Mount Devices (SMDs)

SMDs are the backbone of SMT assembly, encompassing a variety of electronic components designed to be mounted on the surface of PCBs. These devices come in various forms, including:

- Resistors: Used to limit current flow or divide voltages.

- Capacitors: Essential for storing electrical energy.

- Integrated Circuits (ICs): Compact chips that perform various functions in electronic devices.

- Diodes and Transistors: Crucial for controlling and directing current flow.

Circuit Boards and Materials

PCBs utilized in SMT assembly are generally constructed from materials such as FR-4 (a flame-retardant fiberglass epoxy), which is highly durable and offers excellent electrical insulation. The quality of the PCB affects the performance and reliability of the final assembled product, making material selection critical during the design phase.

Soldering Techniques

Effective soldering is vital in SMT assembly to ensure strong electrical connections and component stability. The primary techniques include:

- Reflow Soldering: In this technique, solder paste is applied to the PCB, components are placed, and the assembly is heated in a reflow oven to melt the solder.

- Wave Soldering: Though less common for SMT, this process submerges the entire board in molten solder, suitable for through-hole components.

SMT Assembly Process Steps

Preparation and PCB Design

The first step in SMT assembly is meticulous PCB design and preparation. Engineers must consider factors such as component layout, thermal performance, and electrical properties. Software tools for PCB design enable precise positioning of components to optimize space and functionality. Additionally, creating suitable design files for manufacturing ensures that the assembly processes align with the intended design specifications.

Solder Paste Printing

Once the PCB design is finalized, the solder paste is applied through a stencil onto designated areas of the board where components will be placed. This step is critical as the paste must be applied uniformly to ensure proper bonding. Any inconsistencies can lead to defects, compromising the integrity of the solder joints.

Component Placement and Inspection

After applying solder paste, an automated pick-and-place machine positions SMDs onto the board precisely. This automated process greatly enhances speed and accuracy, reducing the chance of human error. Following placement, an inspection process—often using optical inspection systems—verifies the accurate positioning of components and detects any potential issues before soldering.

Optimizing SMT Assembly Production

Automation in SMT Assembly

The integration of automation in SMT assembly represents a significant advancement, allowing for rapid production capabilities and consistency in quality. Automated machinery not only speeds up the assembly process but also improves precision in placing and soldering components. By investing in automated systems, manufacturers can enhance their production efficiency, reduce labor costs, and minimize errors.

Quality Control Measures

Implementing stringent quality control measures is essential to ensure high standards in SMT assembly. This includes:

- In-Process Inspection: Regular checks during various stages of production help catch defects early.

- Final Inspection: Post-assembly inspections, often through Automated Optical Inspection (AOI), confirm that all components are correctly placed and soldered.

- Testing: Electrical testing to validate functionality and performance is critical prior to packaging and shipment.

Reducing Costs in SMT Assembly

Cost reduction strategies in SMT assembly can significantly increase profitability without compromising on quality. Effective approaches include:

- Optimization of Component Selection: Use of cost-effective, yet reliable components can help manage expenses.

- Efficient Production Planning: Streamlining production schedules and minimizing downtime can lead to substantial savings.

- Investment in Technology: Upgrading to advanced equipment may incur initial costs but can significantly reduce long-term operational expenses.

Future Trends in SMT Assembly

Advancements in Technology

As the electronics industry continues to evolve, so does SMT assembly. Innovations such as advanced robotic systems, AI-powered quality control, and new materials are paving the way for more efficient and reliable production methods. These technological advancements promise to further enhance assembly precision and reduce production costs.

Global Market Insights

The global demand for SMT assembly is expected to rise, fueled by increasing electronic device usage across various industries. Market trends suggest a growing emphasis on miniaturization, which requires continuous improvements in SMT assembly techniques to accommodate smaller, more complex devices.

Adapting to Industry Changes

Manufacturers engaged in SMT assembly must remain agile, adapting to shifts in technology, consumer preferences, and supply chain dynamics. As sustainability becomes a priority, the industry is also exploring eco-friendly materials and disposal methods to minimize environmental impact.